Precision Casting Repair & Ironstitch

CAST METAL REPAIR SPECIALISTS

At Precision Casting Repair we have crews that can be mobilized at a moments notice and travel anywhere in the world. We are set up to do all cast metal repairs with a minimum of tear down, which saves you in both materials and downtime. Whether your at a mine site in Arizona or in Saudi Arabia we can handle all of your casting repair needs.

Get a Quote

All quote are free and flexible according to materials and scheduling.

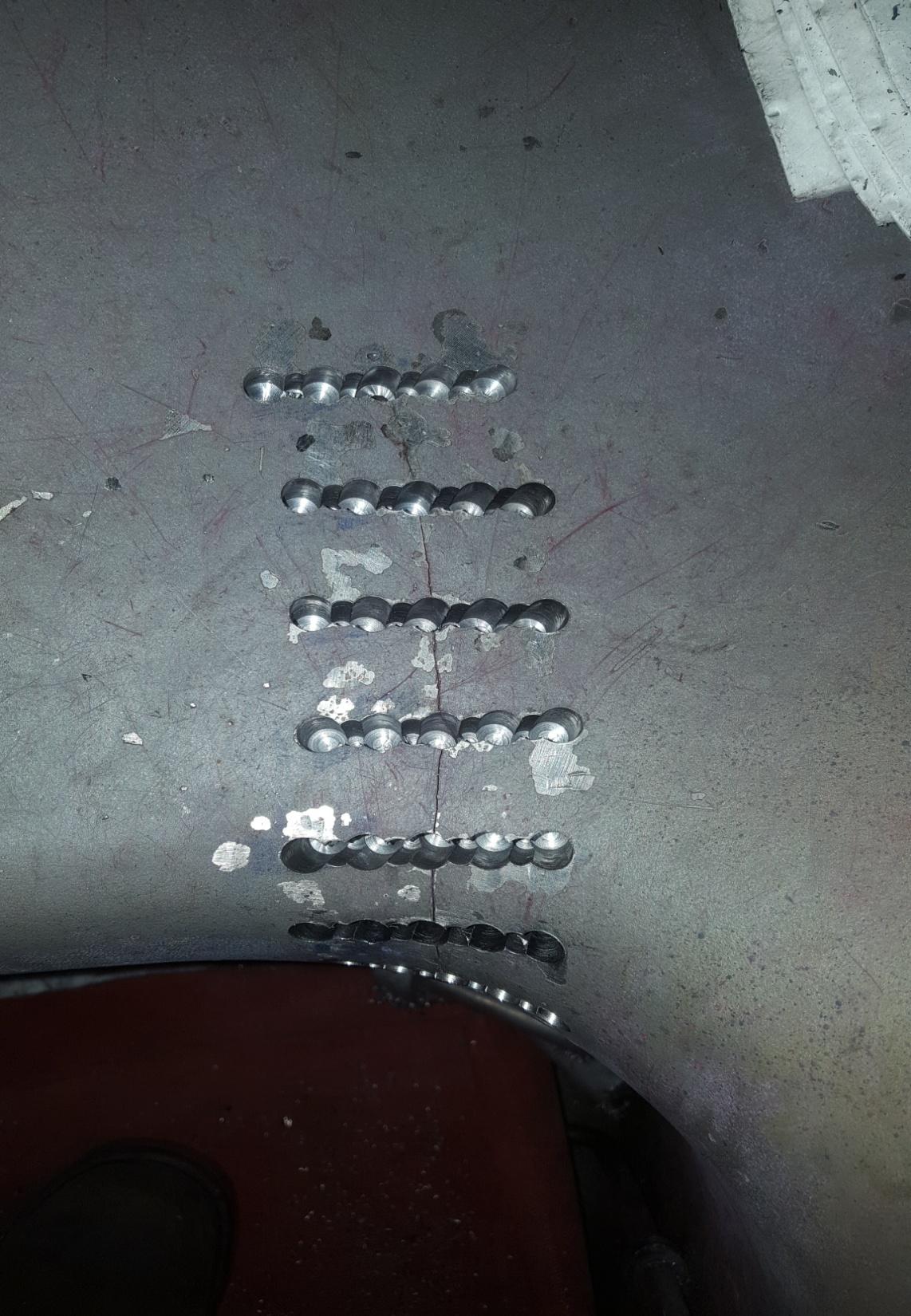

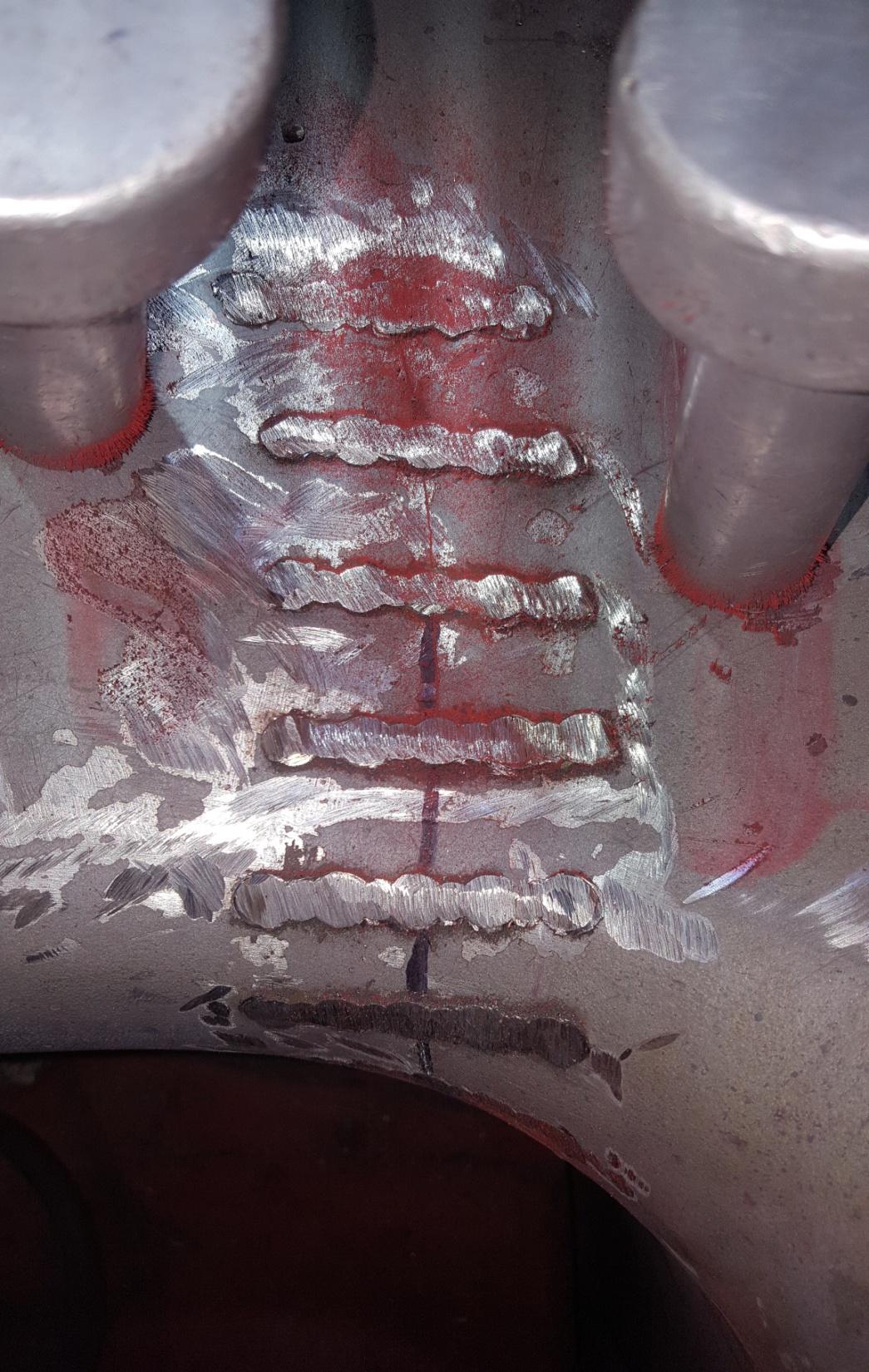

Ironstitch Repairs

Ironstitch is a patented method of mechanically repairing cracks usually found in all types of cast metals. This is performed by drilling out a precise hole pattern...

Furnace Welding

Furnace welding is preheating the entire part to the proper temperature then doing all the welding while the part is at the desired temperature...

Furnace Brazing

One of the benefits to Furnace Brazing is the ability to add steel reinforcements to cast iron to make it stronger than the original part...

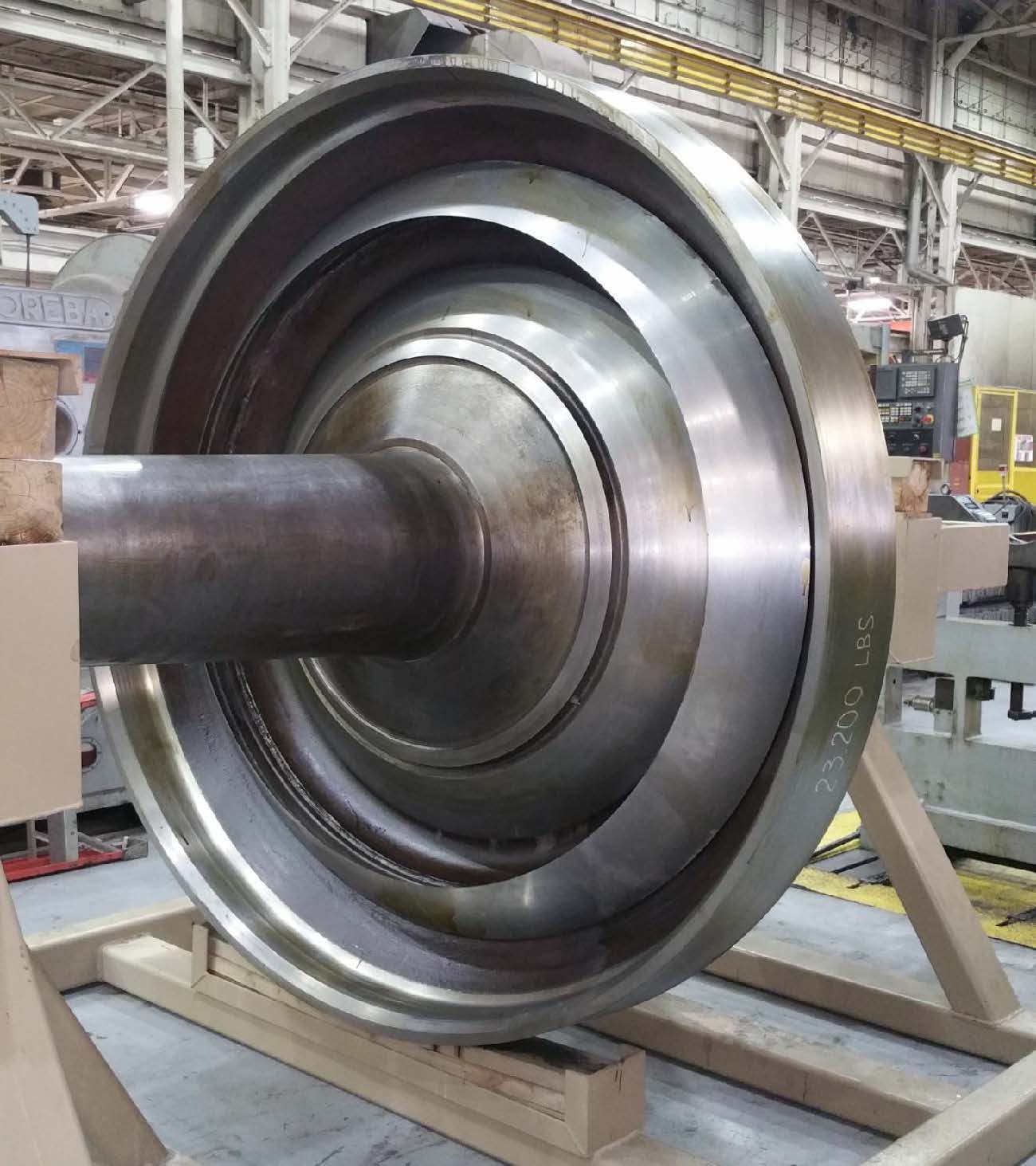

Gear Repair

We travel anywhere at anytime to repair broken teeth on gears. We have the capabilities to get your business back into production...

Our Promise

As your cast metal repair specialist we are here to serve you with all your casting repair needs, whether onsite or in our shop. We can handle the toughest of jobs. Take advantage of our worldwide 24/7 casting repair services.

24 Hour Emergency Mobilization

Our on-site teams are documented with passports in hand. We have the ability to mobilize anywhere in the world at a moments notice.

We know your time and money are important, which is why we specialize in fast - high quality - repairs at an affordable cost for our customers.

On-Site Services

Our on-site services are cost effective. There is no shipping or handling fees.

The tear down is usually less invasive, while minimizing downtime and labor intensive tasks.

Other Services

Cast Iron Fusion Welding

Non Destructive Testing

Ceramic and other Epoxy Coatings

Gears

Engineering of Repairs

Plant Maintenance

Furnace Welding

Stress Relieving

Stainless Steel

Mechanical Services

Fabrication

Machining and Welding

About Us

Cast Metal Repair Specialists

We have a myriad of repair procedures, many are patented and proprietary.

With over 35 years experience in all types of repair from fusion welding to ironstitch, you can trust in our repairs.